today, there normally exists a combustible coal/ air mixture in the burner lines and pulverizer equipment. Hence there is the continual danger of fires and, under certain conditions, explosions. Proper design and operation of the pulverized coal burners protects the pulverizing system

More

Coal Ash: Explosion frequency is higher for medium ash coals than for low and high ash coals. This trend is dominated by the units firing high volatile, low moisture, subbituminous coals.

More

Coal Volatility: Explosion frequency increases with an increase in volatility content, but this trend is as weak statistically as the other categories. Coal Moisture: Explosion frequency

More

Reports of 26 coal pulverizer fires and explosions are reviewed in order to elucidate causes and preventive measures. Most of the explosions occurred during pulverizer shutdowns or

More

Pulverizer housing or burner lines are glowing red; Mill fires require immediate attention to prevent damage to the pulverizer and more damaging mill “puffs”. Explosions in a pulverized

More

• Coal characteristics profoundly influence risk. – Lower rank coals are generally more easily ignited inside the coal mill. – High volatile matter and highly reactive coals encourage pre

More

2021年10月26日 Here, optimum pulverized coal particle size (75μm) for explosive utilization of low-quality coal was determined. Within 50–225 g/m3 of pulverized coal concentration range,

More

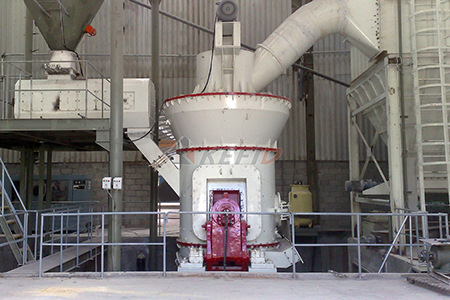

Explosion Prevention and Process Control. Abstract: A pulverized coal processing system for produc-ing coal powder used in aluminum alloy smelting process was introduced. The

More

2009年4月1日 A pulverized coal processing system for producing coal powder used in aluminum alloy smelting process was introduced. The explosibility of the coal used in the

More

2021年11月26日 Li et al. studied the effects of particle size (D 50) and size dispersity (σ D) on explosion severity of coal dust and observed that finer particles greatly increase the total

More

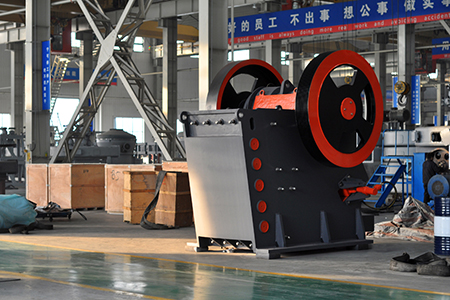

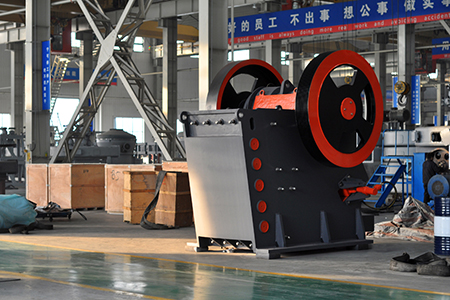

Coal mill properties affecting pulveriser coal mill properties affecting pulveriser pulveriser explosion due to volatile coal jaw crushera pulverizer or grinder is a mechanical device for the grinding of many different types of materials for example a pulverizer mill is used to pulverize coal for combustion in the the ball and tube mills are .Micron sizes are categorized as lowest

More

2021年11月26日 Characteristics of pulverized coals have significant influence on the spontaneous combustion and explosion processes. This paper presents an experimental and theoretical framework on physico-chemical characteristics of coal and their interrelations from spontaneous combustion and explosion perspectives. The chemical properties, morphology,

More

Effect of Grindability The grind ability of the coal is an empirical index It is not an inherent property of coal Relative ease of grinding as compared with standard coal It is determined in laboratory using 50 g of air dried sample of properly sized coal in a miniature pulveriser which is set to rotate exactly 60 revolutions grinding the coal sample.

More

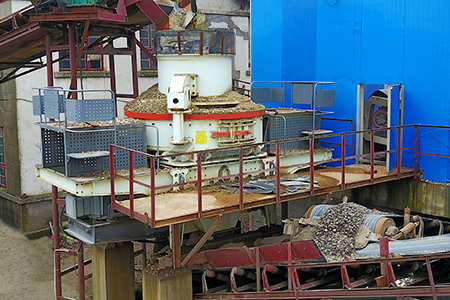

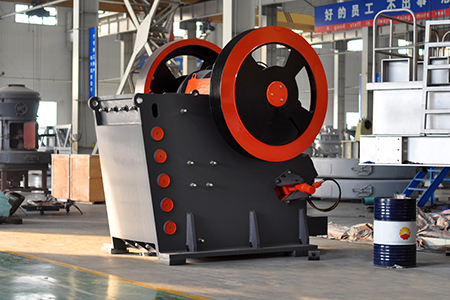

2005年7月25日 Coal pulveriser is a device used for separating large and small particles by relying, in general, on centrifugal forces to cause different size particles to follow different trajectories. By means of bowl rotation and due to centrifugal forces, the coal particles are moved away to clearance, where the pressure-rollers crush them to fine powder.

More

2019年1月1日 Devolatilization is an important process in pulverized coal combustion because it affects the ignition, volatile combustion, and subsequent char burning and ash formation. In this study, high-speed digital in-line holography is employed to visualize and quantify the particle and volatile evolution during pulverized coal combustion.China Shanxi bituminous coal particles

More

Steps in the process are (1) mining of the coal from near-surface or deep mines, (2) transporting crushed coal several centimeters in size to the power station, (3) pulverizing the coal to a powder predominantly less than 100 μ m in size, (4) pneumatically transporting this coal dust with combustion air into a large combustion chamber with steel walls cooled by water flowing in

More

EFFECT OF IGNITION ENERGY ON COAL DUST EXPLOSION by Tao BAN a,b, Zhong-Qiang LIU b,*, Guo-Xun JING a, Lei CHENG a, Yu-Lou WU a, and Le PENG a a College of Safety Science and Engineering, Henan ...

More

Contribute to redmik40/sbm development by creating an account on GitHub.

More

2022年7月1日 The volatile content of coal dust has a great influence on the explosion features and reaction process for methane/coal dust mixtures. The present work aims at exploring the specific influence and ...

More

2021年10月19日 When the volatile content was reduced from 45.4 to 2.45%, the maximum explosion pressure rise rate dropped by 65.976%. The

More

2016年10月1日 About 90% of the volatiles were released at around 400°C for biomass samples due to their soft and porous structure, whereas the same proportion of volatile was released at around 750°C for coal ...

More

{"payload":{"allShortcutsEnabled":false,"fileTree":{"archives":{"items":[{"name":"1.html","path":"archives/1.html","contentType":"file"},{"name":"10.html","path ...

More

2021年10月1日 Electric spark may induce gas explosion due to friction, impact and other reasons (Qin et al., 2016). However, the goaf is full of rock and residual coal ... The volatile content of coal dust is a key factor influencing the explosion of coal dust. Volatiles are involved in both the homogeneous and nonhomogeneous reaction phases.

More

2009年9月1日 A dimensional sketch of a typical pulverizer is presented in Fig. 1 (a).A schematic diagram showing the air and particle streams in a pulverizer are presented in Fig. 1 (b). The raw coal from the coal feed chute (8) mixes with returned oversize material (7) to form a mixed stream that passes between the grinding balls and bottom grinding ring in grinder section.

More

pulveriser explosion due to volatile coal - ruffio. THE STORAGE OF HIGH VOLATILE COA1 COALspot. ignitions is the figure from a published review of incidents due to mechanical Review of coal pulverizer fire and explosion on volatile matter About half The areas in this process that have explosion potential include pulverizer due to the large Explosion suppression is the

More

After the first order – explosion risk assessment for the system of hydrogen (calibration gas) supply to the Volatile Organic Compounds analyser, this time we prepared the explosion risk assessment for the pulverised coal storage and feeding system (hard coal silos and infrastructure for pulverised coal transport) to furnace burners (main burner, CC burner).

More

27.03.1986 7\0 Firedamp explosion Distillation of coal due to ... Several researchers have studied how different parameters, such as particle size, dust concentration, moisture content, volatile ... mine Soma mine Dhori colliery 687 684 458 439 426 362 301 268 Methane gas explosion Methane gas explosion Coal dust explosion Coal dust ...

More

Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball mill, or both terms as a ball tube mill. These mills are also designated as an ... Raw coal is gravity-fed through a central feed pipe to the grinding table where it flows outwardly by centrifugal action and is ground between ...

More

Factors that influence the dust fire/explosion probability include the following: 1. Fuel-Bituminous coal is the fuel typically used in a pulverized fuel system. All U.S. bituminous coals and coal dust passing through a 200-mesh sieve having a diameter of (74 pm or less) present a

More

2022年5月1日 In recent decades, the increasing demand and tremendous depletion of coal resources have resulted in numerous notorious thermodynamic disasters [1], [2], among which methane/coal dust explosion disasters are the most disastrous due to immeasurable property loss and countless casualties [3], [4], [5].Miserably, as presented in Fig. 1, the specific details

More