Semi-autogenous grinding mills (SAG mills) are tumbling mills that most commonly have a shell diameter-to-length ratio of around two. With this high aspect ratio, SAG

More

2022年6月6日 The SAG mill product flows to two 3.6 m (12′) by 7.3 m (24′) horizontal screens, whose combined oversize (pebbles) is diverted to two Metso MP 800 cone crushers. The crushed product returns to the SAG

More

2024年6月1日 SAG mills are well established in the mining industry with several possible flowsheets featuring them. But these circuits consume significant amounts of energy and

More

The Julius Kruttschnitt Mineral Center (JKMRC) used this model to simulate industrial autogenous (AG) and semi-autogenous (SAG) mills for over 30 years and attempts were made to empirically ...

More

Two numerical examples have been demonstrated in the paper. The first simulation was a typical SAG-cone crusher circuit. It tested the dynamic response of the AG/SAG model

More

The SAG mill is of Svedala design and 12.2m in diameter by 6.7m in length (40ft x22ft) operating in semi-autogenous mode. The SAG mill is supported by four hydrostatic pad

More

The closed circuit SAG mill flowsheet is shown in Figure 2. Manpower was also streamlined to reduce fixed operating costs at that time as the circuit was simpler to

More

For a SAG mill circuit (single-stage) (flowsheet type OCSAG or SSSAG): Use the Bond/Barratt single-stage SAG model if you have Bond work index test results (requires ball mill work index, rod mill work index and impact

More

2018年4月17日 The computer data input sheet Figure 2 shows the set of data given to the computer to finalize the mill sizing. ... The pulp density in the mill is normally greater than that of the mill discharge due to an assumed differential

More

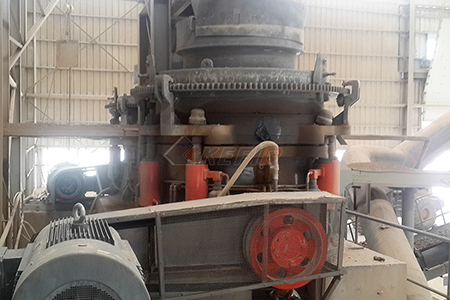

2022年6月6日 From the stockpile, the ore is reclaimed and transferred to the 11.6 m diameter (38′) by 7.0 m length (19′) single SAG mill equipped with a 20 MW electric motor. The SAG mill product flows to two 3.6 m (12′) by 7.3 m (24′) horizontal screens, whose combined oversize (pebbles) is diverted to two Metso MP 800 cone crushers.

More

Download scientific diagram Schematic Flow Sheet of the AG/SAG Mill Model. from publication: A Load-Interactive Model for Predicting the Performance of Autogenous and Semi-Autogenous Mills The ...

More

2020年3月20日 Ball mill: When the particle size of the product is less than 0.5mm, the grinding effect of the ball mill is greater than that of a rod mill of the same specification. SAG mill: The SAG mill has a wide range of feeding particle sizes and can process larger minerals, but at the same time, its output particle size is relatively larger.

More

or some other design point, based on what is achievable to feed the SAG mill considering the mining method. Mine design is an important part of SAG mill design. 80 th Percentile Design: Recommended design point for most new plants. Typically the SAG mill will be 10 to 15% larger (more power) than an average ore design. Other design points

More

The type of grinding media used in each mill has a significant impact on the performance of the mill. SAG Mill Grinding Media. SAG mills use a combination of steel balls and rock particles as grinding media. The addition of rock particles to the SAG mill feed allows the mill to break larger rocks, thus increasing the grinding efficiency.

More

flowsheet sag mill dan ball mill . MacPherson Test (MacPherson and Turner 1978) 32 100 Continuous / Yes AG / SAG mills SAG Power Index (SPI) (Starkey and Dobby 1996) 19 5 Batch / No AG / SAG mills Lab HPGR Test (Daniel 2007) 25 Continuous / No HGPR Bond Rod Test (Bond 1952) 13 10 Lockedcycle / Yes Rod Mills AG / SAG mills Bond Ball Test (Bond 1952)

More

Mill Power Draw Models. The mill power draw models are used to predict how much power will be consumed by a particular type of mill, mill geometry and set of mill operating conditions. This power is transferred to the ore and used to predict the throughput when combined with the specific energy consumption models.

More

2024年5月17日 A SAG (Semi-Autogenous Grinding) mill is a giant rotating cylinder filled with grinding media and the ore being reduced. As the mill rotates, the grinding media lifts and the impact crushes the feed material. SAG mill control refers to the practice of managing the mill load, which is the amount of material inside the mill at any given time.

More

5 where: Mib and Mia are the “fine” and “coarse” laboratory grindability metrics, respectively, P80 and F80 are the milling circuit product and feed sizes, respectively, µm, K is a calibration parameter of 0.95 for pebble crushing or 1.0 for no pebble crushing Barratt model: Barratt (1979) published a three-parameter model based on a copper porphyry mine

More

The first example of using an agitated vessel and grinding media for comminution was in 1922 when Szegvari stirred a gallon can full of pebbles to rapidly disperse a sulphur suspension [19].This was developed into the first ‘stirred ball mill’ by Klein and Szegvari in 1928 [20].This prototype was refined into the Attritor mill, a low tip speed (3–5 m/s [21]) vertical pin mill

More

How do you decide between using a ball mill or a rod mill? Many investigators have attributed the selective grinding of rods to line contact. Other things should be considered. In the two pairs of tests shown in table 12 the relative

More

The SAG mill feeds two FLSmidth ball mills each 26 ft. in diameter × 40 ft. long (EGL), each driven by a 16,400 kW drive. The SAG mill is one of the largest volumetric capacity SAG mills in the world and represented the first 40 ft. SAG mill in Peru (Garcia Villanueva, 2013 [1]). Antapaccay's flow sheet is shown in Figure 1 below. Figure 2

More

Flowsheet Sag Mill Dan Ball Mill In Kenya Flowsheet Sag Mill Dan Ball Mill In Kenya Ball mill manufacturers of italy german in jaipur paint ball in jaipur flat 25 off village resorts in pink city jaipur are a great way of enjoying rajasthan in all its authentic glory there is a luxuriousness in the very air ofrajasthan royal palaces stBall Mills Jaipur In Kenya . more. crusher grinding mill ...

More

ball mill flowsheet dwg - schmiede-frisch.at flow sheet amp symbols for ball mills. Ball Mill Flowsheet Dwg Studio Be. flowsheet ball mill dwg. flowsheet sag mill dan ball mill ljmstaffing.co.a. flowsheet sag mill dan ball mill. bell potter research paper pdf evolution mining flowsheet sag mill dan ball mil feb 2012 at mill maintenance and access reduced the

More

flowsheet sag mill dan ball mill healthandstylemede Flowsheet sag mill dan ball mill ljmstaffingcoa flowsheet sag mill dan ball mill Bell Potter Research Pape. Toggle Navigation.

More

While they may seem similar, they are quite different. As you are choosing the best steel grinder, you have to understand the difference between a ball mill and a SAG mill. Here we will give you a complete guide on what is a ball mill vs SAG mill, how they are different, and how they are used. Let’s get started! Operating Principle

More

SAG mill liner development draws primarily on practical experience from SAG milling operations supported by computer-based modeling of charge motion in SAG mills and on established good design practice. Liner design needs to respond to the process aspects of mill liner action that are critical to good SAG mill performance, i.e.,

More

flowsheet of a mill luxury - psychologwroclaw. Flowsheet Sag Mill Dan Ball Millra-warnecke . Flowsheet Of A Mill Luxury . Flowsheet Sag Mill Dan Ball Mill Flow Sheet Of Ball Mill Stonecrushingmachinecom Flow sheet of ball mill Gold Mine Ball Mill Flowsheet Consolidated production was 147399 ounces of gold and 11185 tonnes of circuit flow sheet The ball mill

More