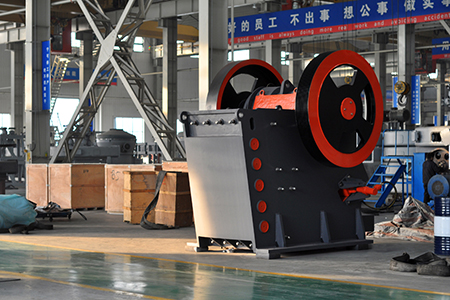

High-Performance Jaw Crushing Plants Designed for Large and Medium-Scale Operators in Quarrying, Demolition, Recycling, and Mining Applications.

More

Model: VYKIN 49-JC Configuration: Jaw crusher Power System: Diesel-direct drive Engine: Yanmar tier 4 certified EPA diesel engine (48HP 35.5kW) Fuel Consumption: 1.3 – 2.1 gal/hr, 26.4 gal capacity Electrical Control: Yes, wireless remote standard Hydraulic Control: Yes, tracks (rubber) Capacity: 20-49 TPH Crushing material: softer-to-medium hard

More

The Powerscreen Premiertrak 400X Jaw Crusher is designed for medium scale operators in quarrying, demolition, recycling, and mining applications. Quote. Sign Up. Skip to Main Navigation; ... (441 US tph) 400tph (441 US tph) Width: 9'2" Length: 51'10" Height: 11'2" Width: 2.8m Length: 16.1m Height: 3.4m ...

More

Optimum jaw nip angle reduces laminar product shape, ensures even manganese wear-off with increasing production. Propel’s track mounted mobile jaw crushers become an extension of your workflow, seamlessly integrating into your existing systems and empowering you to optimize production, wherever your work takes you.

More

A jaw crusher with a wider and shallower jaw can be referred to as a granulator. ... Feed Opening In (MM) recommended Max feed size Range of discharge opening (MM) Crushing capacity (tph) Motor power (kw) SEJ: 250 x 1000: 210: 25 - 60: 16 - 52: 30 / 37: SEJ: 250 x 1200: 210: 25 - 60: 20 - 60: 37: SEJ: 300 x 1300: 210: 20 - 90: 20 - 144: 75 ...

More

Crusher Speed: 300 rpm: Grizzly Feeder: 4240mm (13’ – 11”) x 1064mm (41.9″) Hopper Volume: 5.6m³ (7.3yd³) Belt Width – Main Conveyor: ... More information The McCloskey J45 high capacity Jaw Crushers feature a true 45” x 27” jaw. With both level and load sensors the J45 ensures the most efficient material handling across ...

More

Sandvik QJ341 mobile jaw crusher features a 1,200 x 750mm (47 x 29 in.) jaw opening, built to tackle the most difficult applications with ease. It has been designed to meet the needs of the operator seeking a high performance mobile jaw crusher which is

More

2023年2月23日 A 300 tph crusher plant is a versatile crushing solution that can be used in a variety of industries. Here are some of the key applications of a 300 tph crusher plant: Mining – A 300 tph crusher plant is a valuable asset for mining operations, as it can be used to crush and recycle a wide range of materials, including hard rock and ore.

More

Jaw crushers are used mainly in first stage, primary crushing applications and are ideal for use in quarries and recycling demolition operations. The two main types of jaw crusher produced by Parker are both single toggle designs with the up-thrust toggle RockSizer / StoneSizer model and down-thrust toggle RockSledger model.

More

A new model of our largest sized Trimax Trent Jaw Crusher has been introduced to replace the older Trimax Trent 60-48 Jaw Crusher. This is the Trimax Trent JC160 Jaw Crusher. This new model has been designed with strengthened steel frame construction but yet, with a relatively lighter overall crusher weight.

More

Nordberg® C130™ jaw crusher is commonly used as a primary crusher, preparing material feed for the secondary crusher. However, even though it is traditionally seen at the first stage of the crushing process, this crusher also performs well in other roles, depending on the processed material and application.

More

In this article, we've discussed what is jaw crusher, its types, working and how to use it. Crushers MENU . Jaw ... 385-825 TPH – NF Jaw Series — Screeners. 80 TPH – VYKIN 80-S; 550 TPH – Tracked Screen Plant — Conveyors. 23′ Micro Conveyor; 28′ Micro Conveyor;

More

1 to 5 TPH Rock Crusher for small scale gold and silver mining applications, as well as construction and laboratory testing. top of page. BUILD YOUR WAY INTO PRODUCTION. Cart. HOME. DC Impact

More

2014年12月13日 The jaw Crusher by Apollo evolved from world famous GERMAN TECHNOLOGY and is best in the class in terms of productivity reliability. Single toggle jaw crushers are designed to impart on a rock particle placed between a

More

The heartbeat of the machine is the renowned and aggressive Terex 1000 x 600mm (40” x 24”) jaw crusher with a proven pedigree in recycling, demolition and aggregate production applications. The hydrostatic drive gives the operator the flexibility of variable crushing speed and the ability to run the chamber in reverse in certain applications.

More

Based on the proven 10570, the New 700i is a more Streamlined and Powerful Tracked Jaw Crusher designed with Contractors in mind. With its user friendly design, the 700i is now easier to manoeuvre onsite and transport around various markets due to its new weight and dimensions while still maintaining the original Jaw Crushing Unit. Featuring Tesab’s new

More

Incorporating a Terex® Jaques JW42 jaw crusher and a heavy duty vibrating grizzly feeder, the Finlay® J-1175 gives optimum production in a range of applications. Its compact size, quick set up times, ease of transport and simple maintenance make the Finlay® J-1175 Tracked Jaw Crusher ideal for quarrying, ...

More

2014年4月1日 Jaw crushers are the most common solution in underground applications when the throughput is below 1000 tonnes per hour, depending somewhat on the scalping solutions. Above 1000 tph, primary gyratory crushers are an option. After the throughput reaches 2000 tph, jaw crushers are very rare, with the exception of a parallel plant layout.

More

J6 Jaw Crusher. Features. N. 1200mm (48″) wide x 864mm (34″) single toggle jaw. N. Choice of CAT or Volvo LRC, Tier 4/Stage 5 engines. N. ... Designed to withstand the toughest conditions worldwide, the J6 delivers high TPH due to its innovative jaw chamber design and enhanced material flow.

More

Nesans premium range jaw crushers are higher capacity stone or mineral processing crusher used in the primary stage and secondary stage of crushing. That is to designed for the capacity range from 50 to 400 TPH, our jaw crushers shall be put into use for stones and minerals with varying crushing and abrasive index.

More

McLanahan’s Universal Jaw Crusher produces more spec material at a lower cost per ton and ensures continuous crushing action with less abrasive wear. Products; Solutions. ... P80 is the percent passing the closed side setting in tph. Can I feed my Jaw Crusher coarse and fine material at the same time? The Jaw Crusher is designed to handle ...

More